Water Cooled Screw Chiller Supply

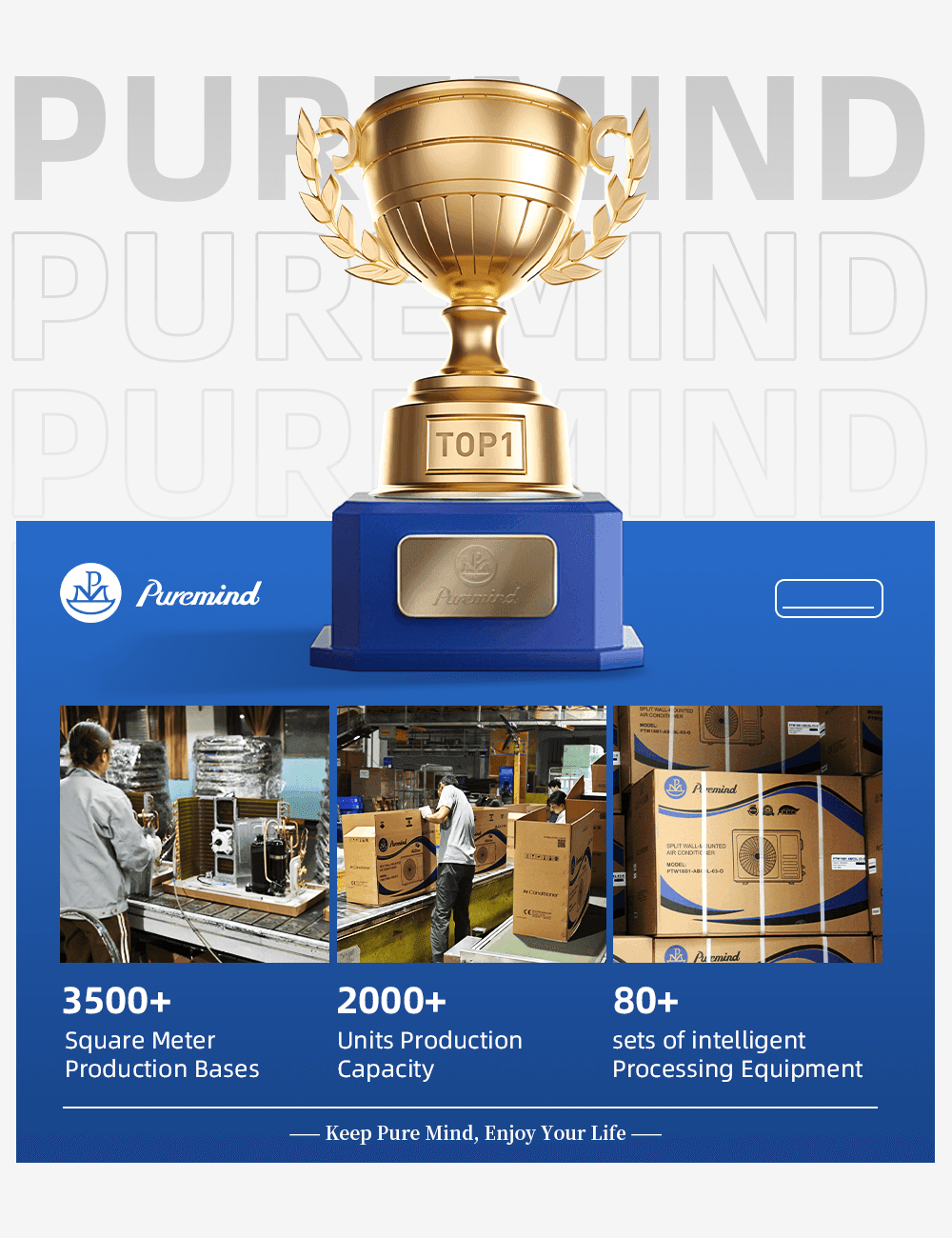

Puremind OEM/ODM Manufacturer

Overview

Puremind water cooled screw chillers are engineered to provide powerful, efficient, and reliable cooling for large-scale industrial and commercial projects. With a cooling capacity range of 100kW to 310kW, these industrial-grade systems are ideal for factories, data centers, hotels, hospitals, and process cooling applications.

Built with advanced screw compressor technology and eco-friendly refrigerants, our screw chillers deliver long-term stability and energy savings. All systems comply with ASHRAE standards and Energy Star efficiency guidelines, ensuring global competitiveness.

Cooling Capacity (100kW – 310kW)

- 100kW — Entry-level water cooled screw chiller for mid-sized factories, hotels, and office buildings.

- 180–240kW — Versatile range for process cooling, supermarkets, and large restaurants.

- 260kW — Suitable for hospitals, schools, and medium industrial applications.

- 310kW — High-capacity system for data centers, pharmaceutical production, and industrial plants.

Key Features

- High Efficiency — Screw compressors with optimized rotor design achieve excellent COP and IPLV performance.

- Reliable Operation — Continuous duty design for 24/7 industrial and commercial applications.

- Stable Performance — Water-cooled condenser ensures high efficiency even in hot climates.

- Eco-Friendly Refrigerants — Available with R134a, R407C, or low-GWP options.

- OEM/ODM Support — Branding, configuration, and packaging customized for distributors.

Technical Advantages

- Screw Compressor Technology — Robust design provides high efficiency, low vibration, and long lifespan.

- Modular Design — Flexible system expansion and easy capacity scaling.

- Advanced Controls — PLC or microprocessor-based controls for precise monitoring and protection.

- Quiet Operation — Screw compressors with noise reduction technology suitable for indoor installation.

- Certification — CE, RoHS, ISO compliance for global market access.

Applications

Puremind water cooled screw chillers are widely used in:

- Industrial Manufacturing — Injection molding, chemical plants, and electronics cooling.

- Data Centers — Precision cooling for server rooms and IT facilities.

- Hospitality — Hotels and resorts requiring reliable central cooling.

- Healthcare — Hospitals, laboratories, and pharmaceutical production.

- Food & Beverage — Dairy processing, breweries, and cold storage facilities.

For more industrial cooling options, see our

Industrial Chiller Catalog.

Water Cooled vs Air Cooled Screw Chillers

When choosing between water cooled screw chillers and air cooled screw chillers, key differences include:

- Efficiency — Water cooled systems typically achieve higher efficiency and lower operating costs.

- Installation — Water cooled units require cooling towers and additional water systems, while air cooled units are simpler to install.

- Applications — Water cooled chillers are suited for large, continuous loads; air cooled units are often preferred for smaller projects with limited water availability.

Energy Efficiency & Compliance

Puremind water cooled screw chillers are engineered for high efficiency and compliance with international standards:

- High COP and IPLV ratings for reduced energy costs.

- ERP labeling available for European markets.

- Certified with CE, RoHS, ISO standards.

- Aligned with ASHRAE and Energy Star benchmarks.

Installation & Maintenance

- Requires cooling tower, condenser water pump, and piping systems.

- Designed for stable 24/7 operation with long service intervals.

- PLC-based monitoring enables predictive maintenance.

- Easy access to compressors, heat exchangers, and electrical panels for service.

Market Trends & Opportunities

The water cooled screw chiller market is expanding due to increasing demand for high-efficiency HVAC systems in industrial and commercial facilities. With rising energy costs and stricter environmental regulations, low-GWP refrigerants and inverter-driven screw chillers are gaining popularity. Puremind supports distributors and contractors with OEM/ODM customization, scalable production, and technical support to meet these evolving needs.

Why Choose Puremind?

- OEM/ODM Expertise — 10+ years in industrial chiller manufacturing.

- Full Range — 100kW–310kW water cooled screw chillers.

- Reliable Quality — Premium compressors, heat exchangers, and electronic controls.

- Certifications — CE, RoHS, ISO, ERP aligned with ASHRAE standards.

- Comprehensive Support — Technical training, documentation, and after-sales service.

Customer Value

By choosing Puremind, distributors and contractors can expand their industrial cooling portfolio with high-performance water cooled screw chillers. From 100kW compact units to 310kW large-capacity systems, Puremind OEM/ODM solutions deliver energy efficiency, reliability, and brand flexibility for diverse markets worldwide.

Get a Quote

Looking for a professional water cooled screw chiller manufacturer?

Contact Puremind today for catalogs, specifications, or quotations on 100kW–310kW screw chiller projects.