HVAC Manufacturing and Technology Guide for Wholesalers, Suppliers & Distributors

The HVAC industry is undergoing rapid transformation driven by advanced manufacturing techniques and cutting-edge technologies. For wholesalers, suppliers, and distributors, understanding HVAC manufacturing and technology trends is essential for staying competitive and delivering the most efficient, eco-friendly solutions to customers. This guide explores the key developments in HVAC production, design innovations, and emerging technologies that are reshaping the market.

What is HVAC Manufacturing and Technology?

HVAC manufacturing and technology refers to the processes, materials, and innovations used to design, produce, and improve heating, ventilation, and air conditioning systems. It covers everything from raw material selection and production methods to digital tools like IoT, AI, and energy optimization software. The primary goal is to produce systems that are energy-efficient, durable, and compliant with international standards.

Core Components of Modern HVAC Manufacturing

- Advanced Materials: Use of corrosion-resistant metals, composite materials, and improved refrigerants.

- Precision Engineering: CNC machining and robotic assembly to ensure consistent quality.

- Modular Design: Systems built for easier maintenance and scalability.

- Quality Control: Automated testing and compliance with ASHRAE standards.

Technologies Driving the HVAC Industry Forward

The pace of innovation in HVAC is accelerating, thanks to several technological advancements:

- IoT Integration: Smart HVAC systems allow for real-time monitoring, remote control, and predictive maintenance.

- AI-Driven Optimization: Machine learning algorithms enhance energy efficiency by predicting usage patterns.

- Energy Recovery Systems: Capturing waste heat to improve system efficiency.

- Eco-Friendly Refrigerants: Transition to low-GWP (Global Warming Potential) refrigerants in compliance with environmental regulations.

- Variable Refrigerant Flow (VRF) Technology: Precise control over multiple zones to reduce energy waste.

Impact on Wholesalers, Suppliers, and Distributors

For those in the supply chain, advancements in HVAC manufacturing and technology present both opportunities and challenges. Staying ahead means offering products that align with regulatory changes, customer demand for energy savings, and the push for sustainable solutions.

Key Benefits

- Access to high-efficiency systems that attract eco-conscious buyers.

- Enhanced reliability and durability of products, reducing warranty claims.

- Stronger market positioning through the adoption of cutting-edge solutions.

- Increased sales potential in commercial and residential projects seeking green certifications.

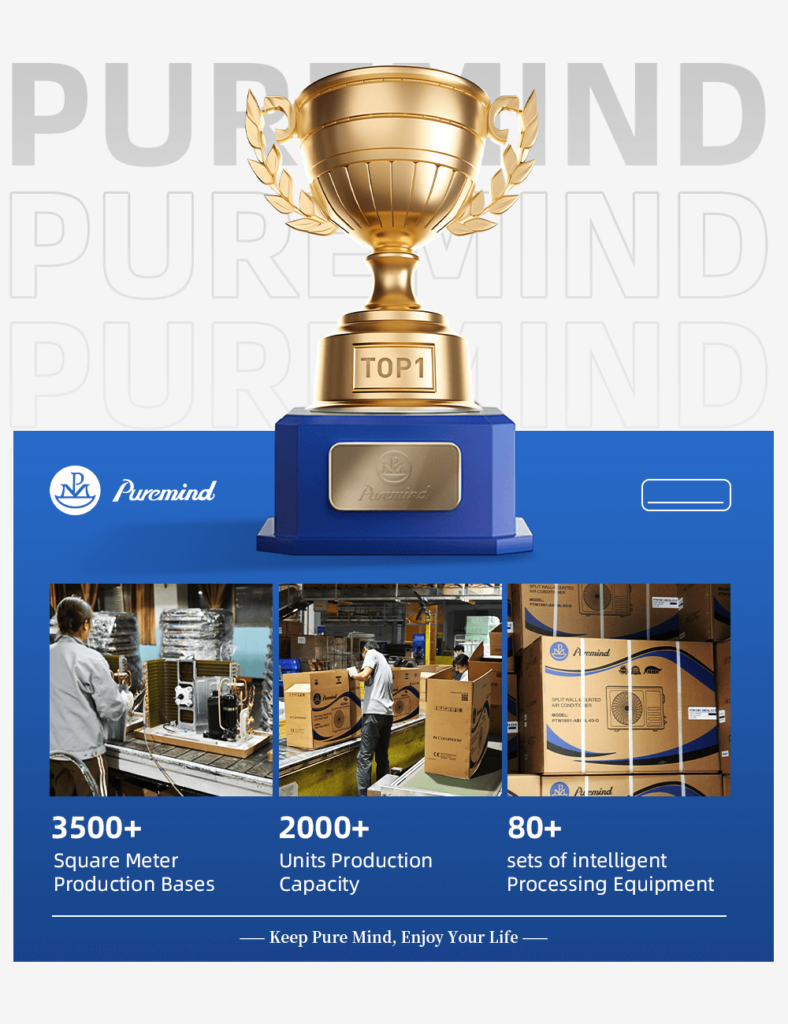

Case Example: Split Air Conditioner Manufacturing

One of the most competitive product categories in the HVAC market is the split air conditioner. Modern manufacturing incorporates IoT sensors, inverter-driven compressors, and eco-friendly refrigerants to meet both performance and environmental goals. Distributors and suppliers can explore a range of models in the split air conditioner category to meet varying customer requirements.

Regulatory Compliance and Industry Standards

Manufacturers must adhere to strict performance and safety standards set by organizations like ASHRAE and governmental agencies. This includes regulations on refrigerants, energy efficiency ratings, and system safety protocols. Compliance ensures that products are eligible for incentives and certifications, which can be a selling point for distributors.

Emerging Trends in HVAC Technology

- Decarbonization: Shift towards low-carbon heating and cooling systems.

- Integration with Renewable Energy: HVAC systems powered by solar or wind energy sources.

- 3D Printing of Components: Reducing production time and material waste.

- Augmented Reality for Maintenance: Technicians using AR headsets for guided repairs and diagnostics.

Challenges in Modern HVAC Manufacturing

While the technological progress is exciting, it comes with its own set of challenges:

- High R&D Costs: Developing and implementing new technologies requires significant investment.

- Global Supply Chain Disruptions: Delays in sourcing advanced components can slow production.

- Skill Gaps: Workforce training is essential to handle complex technologies.

- Regulatory Adaptation: Manufacturers must quickly adjust to new environmental laws.

Best Practices for Staying Ahead

Wholesalers, suppliers, and distributors can take proactive steps to benefit from the evolution of HVAC manufacturing and technology:

- Partner with manufacturers committed to innovation and compliance.

- Invest in staff training on new product features and installation techniques.

- Promote products with documented energy savings and certifications.

- Use digital tools to track inventory and forecast demand for high-tech HVAC systems.

Conclusion

The future of the HVAC industry lies in advanced manufacturing processes and breakthrough technologies. For wholesalers, suppliers, and distributors, embracing these changes means staying competitive, meeting customer expectations, and contributing to a more sustainable world. By aligning with innovative manufacturers and adopting the latest technologies, industry players can ensure long-term success in a rapidly evolving market.